Offset Printing

High-quality, professional offset printing services.

Offset printing is the printing method used for large or commercial-scale print runs and ensures consistency and color accuracy. Our offset presses quickly turnout your large orders with superior quality and flawless images on every printed piece.

How Offset Printing Works

Offset printing or offset lithography is the workhorse of the printing industry and almost every commercial printer does some sort of offset printing. However, a high-quality final product is often due to diligent planning, execution, and equipment provided by your commercial printer.

Offset lithography is based on a very simple principle: ink and water don't mix. Text and pictures are imaged onto printing plates, which are dampened first by water, then ink. Ink adheres to the image area, the water to the non-image area. Next, the image is transferred to a rubber blanket, and from the rubber blanket onto the paper. We call this process "offset" because the image does not go directly to the paper from the plate.

Step 1: Making Printing Plates

Prior to the plate-making process, digital files are arranged on a computer in such a way as to maximize the use of the sheet of paper being used. This process is called imposition. Imposition also helps ensure that when the press sheet is cut and folded, that it is done in such a way to maximize efficiency in the manufacturing process.

Then, before any project can go on press, the digital files are imaged onto metal printing plates. Information from digital files is transferred to the printing plates in much the same way as digital photographs are imaged. A measured amount of light, usually laser light, is used to expose the printing plate in a plate-making system. When exposed to light, a chemical reaction occurs that activates an ink-receptive coating on the printing plate. This results in the transfer of the digital image onto the metal plate.

There are different materials for printing plates, including paper (which produces a lower-quality product) and polyester. The best plate material is aluminum, which is more costly, but provides the quality and durability necessary to produce high-quality offset printing.

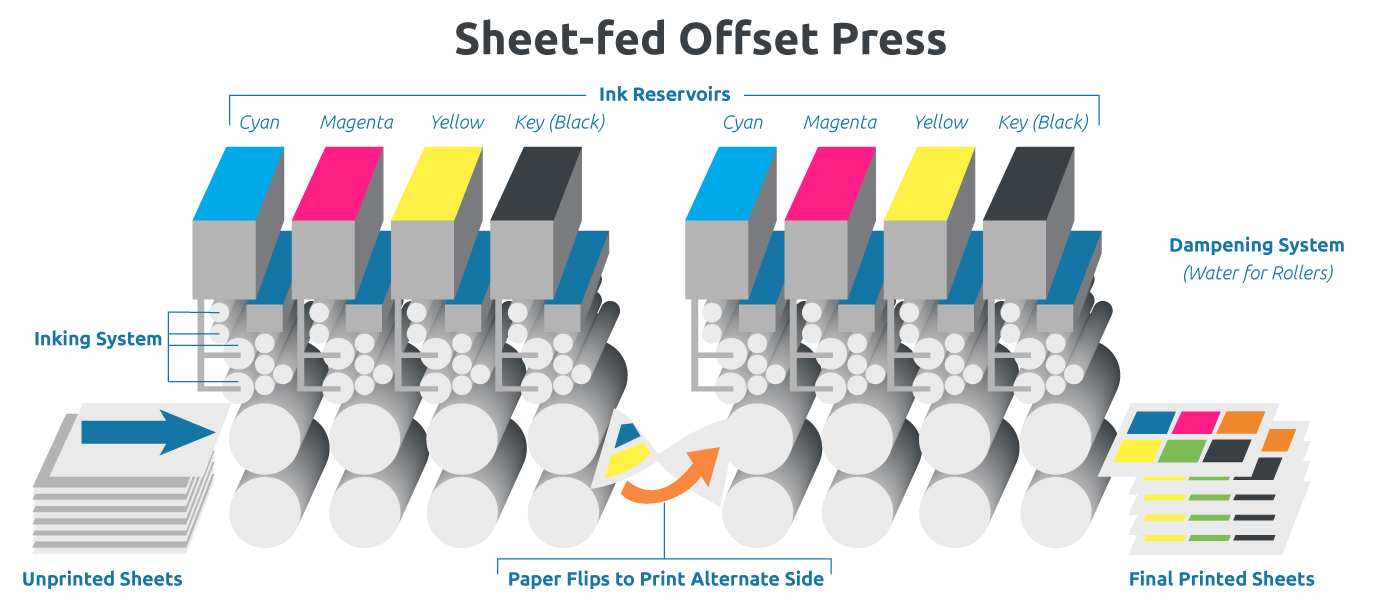

Each of the primary process colors—CMYK or cyan, magenta, yellow, and black—has a separate printing plate. Even though you may see thousands of colors in the finished product, only these four colors are used.

Step 2: The Press Run

At Conquest Graphics we use the sheet-fed method of offset printing. Pre-cut paper is fed through the press as a stack or pile of press sheets. Sheet-fed offset presses print at very high speeds and use very large sheets of paper. Press speeds can reach up to 20,000 impressions per hour. An impression is equal to printing one side of a full press sheet (40 inches x 28 inches.)

As a sheet of paper is fed into the printing press, it will move through a series of rollers and blankets where the ink is transferred onto the paper. A four-color press will have 4 or more “units” which are separate sets of rollers and blankets for each color to be oriented. As the press sheet moves from one unit to the next, another color will be transferred to the sheet of paper.

The ink is transferred to the printing plates through a series of rollers. On the press, the printing plates are dampened, first by the water rollers, then by the ink rollers. These rollers move the ink from the ink fountain onto the printing plates.

The image area of the printing plate accepts ink from the ink rollers. The water rollers help to keep ink off of the non-image areas of the printing plate. Each printing plate then transfers the image to a rubber blanket that in turn transfers the image to the paper. The plate itself never actually touches the paper. This is what is meant by offset printing.

Color and Registration Control

Color and registration control are processes that are controlled by computers. Registration is the alignment of the printing plates as they transfer their respective color images to the press sheet. If the plates do not line up perfectly, the image will appear out of focus and the color will be blurry. As the press runs, a computer scans a set of registration marks that have been placed on the press sheet. Each printing plate has its own individual set of registration marks. The computer reads each of these marks and automatically makes on-the-fly adjustments to the position of each printing plate in order to achieve optimal alignment. All of this occurs many times per second while the press is running at speed.

Color control is a process that controls the placement of ink on the press sheet and is related to plate registration. The amount of ink that is released into the color units depends on how much ink is required to achieve a certain ink density on the press sheet. In modern sheet-fed presses, color control is managed by a computer that is part of the control system of the press. During the press run, press sheets are automatically scanned, and the resulting measurements are used to adjust the amount of ink that is transferred from the ink fountain to the press sheet. This process helps ensure consistent and accurate color reproduction throughout the press run

Step 3: Finishing and Bindery

Finishing and bindery takes place after the press run has completed. Once the printing process has been completed, the printed project is moved to the finishing and bindery department where a wide variety of services take place to enhance the function and overall appearance of the printed piece. This includes scoring, trimming, folding, die-cutting, drilling, binding and more.

For multi-paged printed materials, like catalogs and booklets, bindery is where the printing manufacturing process is completed. Press sheets have been run through the press, allowed to dry, and transported to the bindery for finishing. Press sheets are then cut, collated (gathered and arranged) and folded (if necessary) into the appropriate configuration for the desired product. To learn more about the bindery options we offer, including perfect binding, click here.

For brochure printing, sheets are cut down and folded on high-speed folding machines called “folders.” For catalogs and magazines, the press sheets are folded in nested order, so that they can be stitched together (stapled) to form the finished product.

In the stitching process, a machine called a “stitcher” takes the folded press sheets (called “signatures”) and collates them together. Then, stitches (staples) are inserted into the fold of the signatures, binding them together.

The final components in the “stitcher” are the knives, which trim the paper to the final delivered size. The product is then ready to be shipped to the end destination.